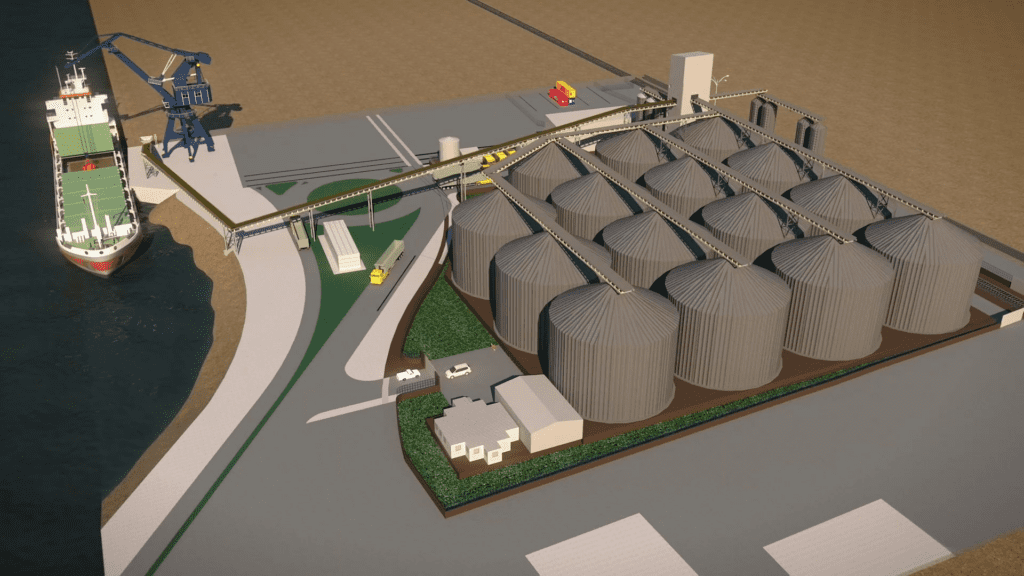

In the dynamic world of logistics, the Nacala Bulk Grain Terminal stands as a beacon of innovation and efficiency. This cutting-edge facility, currently under construction, is poised to revolutionise the way bulk grains are handled in the region. Central to its operational prowess is the sophisticated system of belt conveyors designed to seamlessly manage the unloading and uploading of grains. Let us delve into the intricacies of this vital component, reflecting on its current construction status and anticipated impact.

How will it work?

At the heart of the Nacala Bulk Grain Terminal’s design is a 300 MT/hour crane, a powerhouse engineered to unload grains with precision and speed. This crane will deftly transfer bulk grains from vessels into a hopper, where the belt conveyor system takes over. This conveyor system is not merely a transport mechanism; it is the lifeline of the terminal, ensuring grains are swiftly and efficiently moved either to silos or awaiting trucks & trains, ready for distribution. The conveyors, thus, play an instrumental role in maintaining the flow and integrity of the supply chain, reducing delays, and optimising throughput.

Construction Update

As of now, significant strides have been made in the construction of the conveyor system. The quay and rail side foundations are complete, marking a critical milestone. The current focus is on the foundation head with anchor bolts, a pivotal stage that will provide the structural integrity needed for the entire system. This meticulous approach ensures that once operational, the belt conveyors will function flawlessly.

The Nacala Bulk Grain Terminal is on the brink of transforming grain logistics in the region. With the belt conveyor system at its core, this facility promises to set new standards in speed, efficiency, and reliability.

Stay tuned as we continue to chronicle the development of this monumental project.